Structure.

- Australia 1901-1988

- New South Wales

- Queensland

- South Australia

- Tasmania

- Victoria

- Western Australia

- International

- Special aspects

Structure.

When discussing the cable being laid between Australia and New Zealand, the Sydney Morning Herald of 3 February 1876 described the structure of the cable as follows:

"The cable itself consists of a centre of seven small copper wires, twisted into a cord, through which the electrical current will pass. This central arrangement is overed with gutta percha, forming what is called the "core" being about a quarter of an inch in diameter. This is "served" with a thickness of jute yarn, outside of which is a protective covering of fifteen twisted steel wires. Bound around these are two "servings" of hempen year, twisted in opposite directions, and further protected by coatings of a mixture of tar and pitch".

At that time, Victorians used a product called gutta-percha to make a range of products such as dolls, small ornaments, items of furniture, etc. Gutta percha was a rigid natural latex from the sap of gutta-percha tree found in South-East Asia. It was hard at room temperature but very malleable in hot water and it could be easily molded. Although gutta-percha was expensive:

- it provided an ideal coating of submarine cables because of it being biologically inert, resilient and a good electrical insulator with a high dielectric strength.

- it is useful in dentistry for root canal therapy;

- it was used to make pistol hand grips and rifle shoulder pads before bakelite was invented;

- it was used to make golf balls by providing a solid core and that design revolutionised the game.

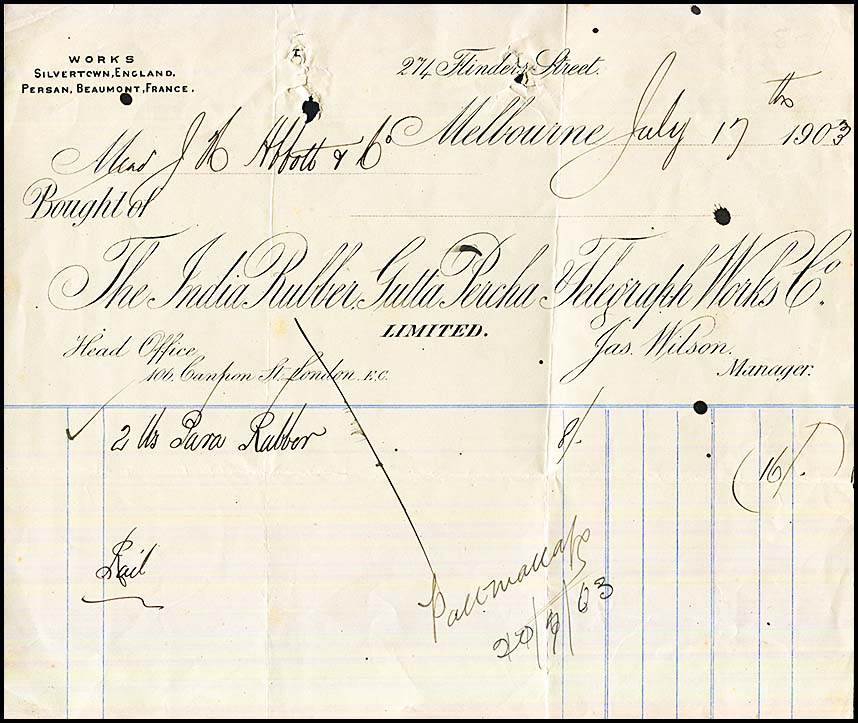

The India Rubber, Gutta Percha Telegraph Works Co. was then formed in England in 1845. Its first efforts were directed towards making stoppers for bottles. In 1848 it learnt of the increasing activity in developing telegraphic cables and so it changed one of its machines so as th be able the coat a copper wire with a thick layer of gutta-petcha. That worked very well and, up too about 1865, the Gutta-Pecha Company had a monopoly in making submarine cables. Its factories were at Silvertown in England and Persan, Beaumont in France. Gutta-percha became so much in demand that the trees were harvested in unsustainable numbers and the supply collapsed.

|

Example of a telegraphic cable.

| The cable used had a stranded central conductor covered with a layer of insulation. The insulation was covered by two layers of fibrous material (probably hemp) in strands of about 5 mm diameter. The two layers were laid in opposite directions. The outer layer of fibrous material was surrounded by possibly 12 armouring wires with each wire about 6 -- 8 mm in diameter. |  Part of the 1875 cable. Source: Museum of Victoria ST 007068 |

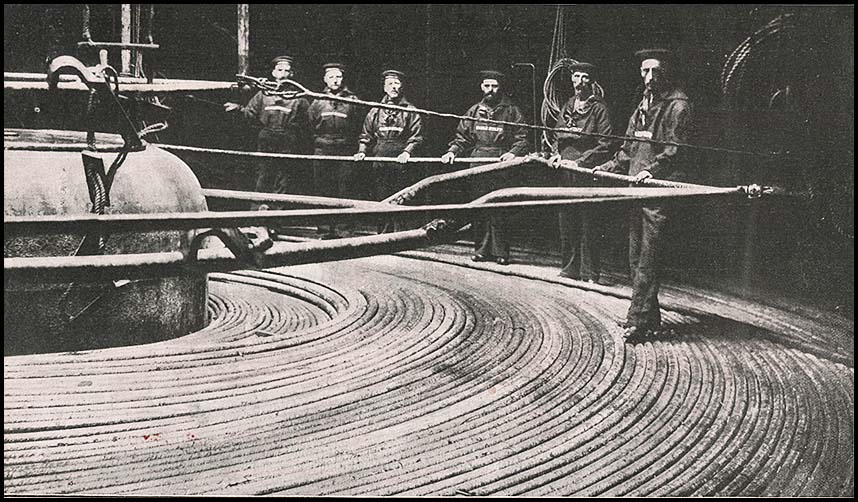

There are a number of references on other pages describing that "the cable ship liad the cable ...". Sometimes that procedure was over a short distance. At other times, the distances were very significane - for example the British cable and the US cable across the Pacific. Even the Aden to Madras, the Singapore to Batavia cable and then to Port Darwin were across significant distances.

As described for the S.S. Great Eastern and for laying the New Zealand cable, there were sometimes three areas set aside in the Cable Ships to store the cables. A view of the cable being played out from the Cable Steamer Silvertown is shown below.

Paying out the Cable on board the "Silvertown". Image scanned from the journal B;ack and White, 10 January 1903. |